Sunday, November 28, 2010

What are Motor controls and how they work

Motor controls a quick summary

Motor controls are those devices that operate electric motor particularly, those high powered electric motors used to operate machines like electric drilling machines, wood lathe machine, electric bending machine and those other machine used in the industry plant.

Motor controls can be divided into three major types;

1. Manual- The construction of the controllers here constitutes only simple devices requiring the operator to go into the controller location to initiate the change in the state of the control system. the installation of the controller to the motor is simply done by connection of the switch in series withe the motor.

2. Semi-automatic-This type of controller is characterized by the use of push button, pressure switches , limit switches and other sensing devices to control the operation of magnetic contactor or starter. The operator must still initiate some actions such as starting and stopping but he does not have to go the location of the motor or the starter to perform the operation.

3. Automatic- Similar to semiautomatic, an automatic controller is characterized by the use of sensing devices.With an automatic control, the operator doest have to initiate certain actions. After that the operation is set , the system will continue to operate in its own.

Semi-automatic and automatic controllers are generally employed with an overload or low voltage release protection to shut down the system automatically for protection of the device and the operator.

Motor Controls involves the use of the following devices like magnetic starters and push button station and the use of cables to connect this devices. This cables maybe any of the following, BX cable ,loomex cable,steel conduit wiring.For push button stations it can be a start-stop, forward-reverse-stop push button and the start-jog-stop push button. For Push button types it can be a normally open or closed push button,stacked push button, push pull buttons and lighted push buttons. Push buttons can make or break the connection in a control system.

Motor Controls are divided into the following

1.Motor controls for alternating current (AC)machines or motors

2 Motor controls for Direct current (DC) machines or motors

Motor controls are those devices that operate electric motor particularly, those high powered electric motors used to operate machines like electric drilling machines, wood lathe machine, electric bending machine and those other machine used in the industry plant.

Motor controls can be divided into three major types;

1. Manual- The construction of the controllers here constitutes only simple devices requiring the operator to go into the controller location to initiate the change in the state of the control system. the installation of the controller to the motor is simply done by connection of the switch in series withe the motor.

2. Semi-automatic-This type of controller is characterized by the use of push button, pressure switches , limit switches and other sensing devices to control the operation of magnetic contactor or starter. The operator must still initiate some actions such as starting and stopping but he does not have to go the location of the motor or the starter to perform the operation.

3. Automatic- Similar to semiautomatic, an automatic controller is characterized by the use of sensing devices.With an automatic control, the operator doest have to initiate certain actions. After that the operation is set , the system will continue to operate in its own.

Semi-automatic and automatic controllers are generally employed with an overload or low voltage release protection to shut down the system automatically for protection of the device and the operator.

Motor Controls involves the use of the following devices like magnetic starters and push button station and the use of cables to connect this devices. This cables maybe any of the following, BX cable ,loomex cable,steel conduit wiring.For push button stations it can be a start-stop, forward-reverse-stop push button and the start-jog-stop push button. For Push button types it can be a normally open or closed push button,stacked push button, push pull buttons and lighted push buttons. Push buttons can make or break the connection in a control system.

Motor Controls are divided into the following

1.Motor controls for alternating current (AC)machines or motors

2 Motor controls for Direct current (DC) machines or motors

Saturday, November 27, 2010

A review Complex number

Complex number review

Complex number are usually discussed in the first part of advanced mathematics and here is a quick review about it.

Consider the equation

it has has NO SOLUTION in real number system.

But in eighteenth century mathematician invented a new number "i" which is defined by the property. this in turn , led to the development of complex numbers, which are numbers of the form a+bi .

"a "and "b" are real numbers. But it can be also observed that every real number a is also a complex number because it can be written as a=a+0i. Thus ,the real numbers are a subset of the complex numbers.

With these properties complex number can be now defined as.

---the combination of real and imaginary number which can be expressed in the form a+bi or a+jb where i or j=-1

Powers of i or j

Note for j^n

If n is divided by 4 and the result is 1 it follows j^4. if the result has a decimal value of (.75) if follows j^3.If (.50) it follows j^2. If (.25) it follows j

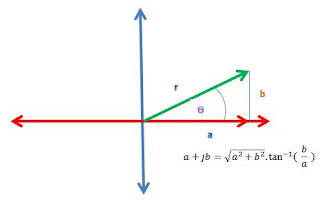

Argand's diagram

real axis

Forms of complex numbers -complex number can be expressed in different notations.

1.) rectangularr form -complex number is denoted by its respective horizontal and vertical components.

a+jb where: a-real value

jb-imaginary axis

2.) polar form - complex number can be denoted by the length and the angle of its vector

r∠Ɵ where: r- magnitude

Ɵ - argument,degrees

3.) trigonometric form

rcosƟ +jsinƟ where: r-magnitude

Ɵ-argument,degrees

4.) Exponential form

where: r-magnitude

Complex number are usually discussed in the first part of advanced mathematics and here is a quick review about it.

Consider the equation

it has has NO SOLUTION in real number system.

But in eighteenth century mathematician invented a new number "i" which is defined by the property. this in turn , led to the development of complex numbers, which are numbers of the form a+bi .

"a "and "b" are real numbers. But it can be also observed that every real number a is also a complex number because it can be written as a=a+0i. Thus ,the real numbers are a subset of the complex numbers.

With these properties complex number can be now defined as.

---the combination of real and imaginary number which can be expressed in the form a+bi or a+jb where i or j=-1

Powers of i or j

Note for j^n

If n is divided by 4 and the result is 1 it follows j^4. if the result has a decimal value of (.75) if follows j^3.If (.50) it follows j^2. If (.25) it follows j

Argand's diagram

real axis

Forms of complex numbers -complex number can be expressed in different notations.

1.) rectangularr form -complex number is denoted by its respective horizontal and vertical components.

a+jb where: a-real value

jb-imaginary axis

2.) polar form - complex number can be denoted by the length and the angle of its vector

r∠Ɵ where: r- magnitude

Ɵ - argument,degrees

3.) trigonometric form

rcosƟ +jsinƟ where: r-magnitude

Ɵ-argument,degrees

4.) Exponential form

where: r-magnitude

Ɵ-argument,degrees

Friday, November 26, 2010

How are coils connected in an alternator ?

Alternator coil connections

There are two ways of connecting the coils of the three phase AC generators or alternator in a load. These are the wye or the star connection and the delta connection. Generally, generators are wye connected ( earth wire) but loads can be either delta or wye.

1. Star Connected, 4-wire Alternator

iA

iC

iB

![]() This takes advantage of the fact that the sum of the three phase current is zero

This takes advantage of the fact that the sum of the three phase current is zero

iA +iB iC =0

When the generator has a balanced output and the loads connected to each phase are identical then the calculation of the voltages and current for, say the red phase can be applied equally to two other phases. The voltage in A,B,C are called phase voltages and are the potential difference developed between Vab, Vbc, Vac

2. Delta connected, 3-wire Alternator

In this configuration the connection has no neutral line. The voltage between pair of lines are equal to the phase voltage of the generator and the line current is the difference between the two phase currents.

The line currents are the currents flowing into and from the load where the actual current is the addition of the two.

For balanced poly-phase systems phases have identical line voltages and currents.

iA

iB

iC

This takes advantage of the fact that the tree phase voltages always sum up to zero

This takes advantage of the fact that the tree phase voltages always sum up to zero

Va+Vb+Vc=0

Sources

Electrical engineering training series :Three phase alternator connection

Network analysis 2007

There are two ways of connecting the coils of the three phase AC generators or alternator in a load. These are the wye or the star connection and the delta connection. Generally, generators are wye connected ( earth wire) but loads can be either delta or wye.

1. Star Connected, 4-wire Alternator

iA

iC

iB

iA +iB iC =0

When the generator has a balanced output and the loads connected to each phase are identical then the calculation of the voltages and current for, say the red phase can be applied equally to two other phases. The voltage in A,B,C are called phase voltages and are the potential difference developed between Vab, Vbc, Vac

2. Delta connected, 3-wire Alternator

In this configuration the connection has no neutral line. The voltage between pair of lines are equal to the phase voltage of the generator and the line current is the difference between the two phase currents.

The line currents are the currents flowing into and from the load where the actual current is the addition of the two.

For balanced poly-phase systems phases have identical line voltages and currents.

iA

iB

iC

This takes advantage of the fact that the tree phase voltages always sum up to zero

This takes advantage of the fact that the tree phase voltages always sum up to zeroVa+Vb+Vc=0

Sources

Electrical engineering training series :Three phase alternator connection

Network analysis 2007

Thursday, November 25, 2010

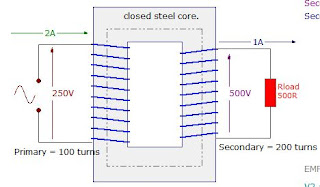

Transformer operation and construction

Transformer: Basic operation and construction

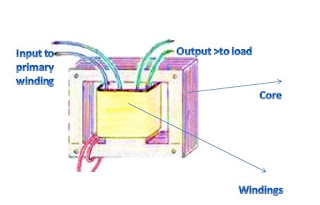

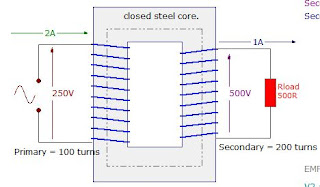

Transformer is an electrical device that converts voltage from one value to another that is, either from high voltage to lower voltage which is termed step- down transformer, or from lower voltage to higher voltage which is termed step up transformer.

The principle behind lowering or raising the voltage is done through magnetic induction between its coils. Changing current in the primary winding creates alternating magnetic field in its the core. And as the core multiplies this field and couples the most of the flux through the secondary transformer windings, It creates an induction of alternating voltage or the electromotive force in each of the secondary coil.

A transformer is constructed with the following essential parts :

1. Core (iron core or air core)

2. Windings ( primary winding or secondary winding)

3. Insulation (major insulation and minor insulation)

The core is made up of of lamination sheets. one of the best used as core is silicon steel

These sheets has its purpose:

a) to hold the windings in place

b) to serve as path for magnetic circuit or magnetic field

The lamination sheets are pressed tightly together leaving no spaces between sheets.

Another essential part of the transformer are the windings. Windings are made up of copper wire generally termed as magnetic wires. These wires are usually covered with varnish insulation. Other magnetic wires beside the varnished insulation are still covered with cotton and generally used for big transformer.

Windings are composed of primary and the secondary winding. The primary winding is the one that is connected to the power supply , the purpose of which is to get the required power. On the other hand, the secondary winding is the one connected to load and deliver the needed power. The secondary maybe one or more windings.

Windings are composed of primary and the secondary winding. The primary winding is the one that is connected to the power supply , the purpose of which is to get the required power. On the other hand, the secondary winding is the one connected to load and deliver the needed power. The secondary maybe one or more windings.

The insulation is used to separate or insulate iron core as well as the windings. There are two types of insulation used in transformer,

a.) major insulation

b) minor insulation. the major insulation is used to insulate or separate the windings from the iron core and insulate or separate the primary winding from the secondary winding. The minor insulation on the other hand is used to insulate or separate one layer of turns to the next layer.

Transformer Operation

When the primary winding is plugged or connected to the power source, magnetic lines of force are developed around the windings and travels within the iron core. By electromagnetic induction principle, these magnetic lines of force travelling around the core induces another voltage to the secondary windings which gives the idea although the primary and the secondary windings are separated or not connected to each other, a lower or higher voltage can be produced in the secondary winding. in this operation of transformer, one must recall his knowledge of the principles of electromagnetic induction.

Sources

Transformer is an electrical device that converts voltage from one value to another that is, either from high voltage to lower voltage which is termed step- down transformer, or from lower voltage to higher voltage which is termed step up transformer.

The principle behind lowering or raising the voltage is done through magnetic induction between its coils. Changing current in the primary winding creates alternating magnetic field in its the core. And as the core multiplies this field and couples the most of the flux through the secondary transformer windings, It creates an induction of alternating voltage or the electromotive force in each of the secondary coil.

|

2. Windings ( primary winding or secondary winding)

3. Insulation (major insulation and minor insulation)

The core is made up of of lamination sheets. one of the best used as core is silicon steel

a) to hold the windings in place

b) to serve as path for magnetic circuit or magnetic field

The lamination sheets are pressed tightly together leaving no spaces between sheets.

Another essential part of the transformer are the windings. Windings are made up of copper wire generally termed as magnetic wires. These wires are usually covered with varnish insulation. Other magnetic wires beside the varnished insulation are still covered with cotton and generally used for big transformer.

Windings are composed of primary and the secondary winding. The primary winding is the one that is connected to the power supply , the purpose of which is to get the required power. On the other hand, the secondary winding is the one connected to load and deliver the needed power. The secondary maybe one or more windings.

Windings are composed of primary and the secondary winding. The primary winding is the one that is connected to the power supply , the purpose of which is to get the required power. On the other hand, the secondary winding is the one connected to load and deliver the needed power. The secondary maybe one or more windings.The insulation is used to separate or insulate iron core as well as the windings. There are two types of insulation used in transformer,

a.) major insulation

b) minor insulation. the major insulation is used to insulate or separate the windings from the iron core and insulate or separate the primary winding from the secondary winding. The minor insulation on the other hand is used to insulate or separate one layer of turns to the next layer.

Transformer Operation

When the primary winding is plugged or connected to the power source, magnetic lines of force are developed around the windings and travels within the iron core. By electromagnetic induction principle, these magnetic lines of force travelling around the core induces another voltage to the secondary windings which gives the idea although the primary and the secondary windings are separated or not connected to each other, a lower or higher voltage can be produced in the secondary winding. in this operation of transformer, one must recall his knowledge of the principles of electromagnetic induction.

Sources

Electrical Transformers Explained How Is Electric Energy Produced

Subscribe to:

Comments (Atom)